Here’s a breakdown of how a Total Tyre Management programme (such as what TyreBook offers) can help fleet operators cut their tyre‐related and overall running costs by ~30%, along with the features and best practices that make that possible. I’ll also sketch how TyreBook (based on what is publicly known of its digital tyre ecosystem) fits into this model.

Why Tyre Costs Matter in Fleet Economics

Tyres are one of the largest variable costs for any vehicle fleet, after fuel and labour. Bad tyres or poorly managed tyres eat into profitability through:

- Premature replacement (worn out or damaged before their useful life ends)

- Increased fuel consumption (due to underinflation, misalignment, bad rolling resistance)

- Downtime / maintenance delays (flat tyres, blowouts, repairs)

- Safety risks and regulatory penalties

If you reduce tyre‐related waste, improve their usage and lifespan, and prevent failures, you can free up a lot of cost savings.

What “Total Tyre Management” Means

A robust Total Tyre Management (TTM) system typically covers the full life‐cycle of tyres in the fleet: from specification & purchase → inventory → installation → monitoring / maintenance → retreading / disposal. Key components include:

- Standardisation & wise purchase decisions

- Selecting tyres suited to load, road conditions, application, climate.

- Comparing brands, rolling resistance, durability vs price.

- Buying tyres with good retread or recapping potential, if that’s part of your operating model.

- Inventory & usage tracking

- Keep detailed records of each tyre: when purchased, installed, on which vehicle, its service history, tyre rotations, retreads, etc.

- A digital or software system helps to avoid mismatches, wrong tyres on wrong vehicle types, and unnoticed overuse or uneven wear.

- Regular maintenance & monitoring

- Maintaining correct tyre pressure. Under/overinflation reduces lifespan significantly.

- Ensuring proper wheel alignment and balancing. Misalignment can reduce life by up to ~25%. ResearchGate+1

- Monitoring tread depth, temperature, and wear patterns so corrective action (rotation, repositioning) can be taken early.

- Predictive and preventive maintenance rather than waiting for breakdowns.

- Driver & staff training

- Drivers often are first line: training to spot irregular wear, underinflation, damage.

- Maintenance teams need routines and standards so that tyres are handled, stored, installed properly.

- Data & analytics

- KPIs such as cost per km (or mile), tyre life (km till retirement), downtime due to tyre issues, fuel penalty due to bad tyres.

- Comparing performance across tyre types, brands, routes, vehicles.

- Using historical data to forecast replacements, budgeting, and to identify problem areas (e.g. certain routes with rough roads, or certain vehicles prone to high tyre wear).

- Lifecycle management (retreading / disposing / recycling)

- Where possible, retreading can extend life and reduce cost per usable km.

- Proper disposal / recycling also avoids hidden costs.

How These Practices Translate Into ~30% Cost Savings

Putting all of the above in place properly can lead to big savings. Here is how those savings roughly add up, and how one might get to 30%:

| Area | Potential Savings / Improvements | Rough Contribution to Total Cost Reduction |

|---|---|---|

| Reduced tyre purchase cost (longer life, fewer replacements) | If tyres last 20-40% longer via better maintenance, alignment, pressure | ~10-15% |

| Fuel savings | Better inflation, less rolling resistance → fuel efficiency (sometimes 2-5%) | ~5-10% |

| Reduced downtime / repair cost | Fewer punctures, blowouts, breakdowns; fewer “emergency” repairs that are costly | ~5-7% |

| Administrative & inventory waste reductions | Avoid overstocking, wrong tyres in inventory, mis‐usage, wastage | ~2-5% |

| Lifecycle improvements (retreading / reusing) | Extending usable tyre life by retreading or using second life where feasible | ~2-5% |

When these accumulate, 20-30% reduction in total tyre‐related cost is quite feasible. If tyres form, say, 10-20% of overall fleet operating expenses, then a 30% cut in tyre costs yields a 3-6% saving overall. If coupled with other cost‐saving measures, fleet TCO (total cost of ownership) can drop substantially.

What TyreBook Brings / How It Fits In

TyreBook is presented as India’s digital tyre ecosystem for transporters, dealers & recyclers. While detailed internal workings aren’t all in public domain, here are how such a platform can enable TTM, and what features are likely / useful:

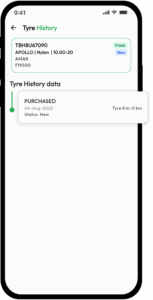

- Digital tracking & visibility: Having a platform to log tyre purchases, installations, service history, positions, inventory, etc., helps eliminate data gaps. You know which tyre is where, how much life is left, what cost has been incurred.

- Marketplace & dealer linkage: For dealers / recyclers and transporters to source tyres, retreads, and services at competitive rates. Having more transparent supply & service options lowers procurement and maintenance costs.

- Analytics & KPI dashboards: Comparing across vehicles, across tyre types, across service providers; seeing “bad actors” (vehicles or routes that consume more tyre cost), enabling corrective action.

- Maintenance scheduling support: Reminders (via digital platform) for pressure checks, alignment, rotation etc. to prevent problems rather than react to them.

- Support for retreading / recycling: Given India has large demand and capacity for retreading and recycling, linking that into the tyre lifecycle reduces waste and cost.

- Standardization & assistance: Tyre specification tools, best-practices guidance, maybe even training / content to help fleet operators, drivers, workshops follow standard protocols.

Given TyreBook’s positioning, a fleet using its services and platform could more easily implement many of the Total Tyre Management practices listed above, leveraging digital tools + network, rather than building everything in-house.

Challenges & What It Takes to Realize the 30%

While the potential is large, getting there isn’t automatic. Key enablers / challenges:

- Discipline & buy-in: Drivers, workshop staff, management must adhere to inspection routines, correct tyre pressure, rotate tyres, etc.

- Data accuracy & culture: Digital tools are only useful if the data entered is accurate and timely (e.g. record of install, service, damage).

- Upfront investment: Sensors, TPMS, alignment machines or services, good quality tyres with strong retreading potential – these often cost more upfront though pay off in lifecycle.

- Effective procurement: Need a good supply chain for tyres, retreads, quality inspections, etc. Also, access to competitive pricing.

- Route / load / road conditions: In many places (especially in developing countries), road conditions are poor. So even well-maintained tyres suffer faster wear. Management must adjust specs and maintenance accordingly.

Summary

Putting it all together: A properly executed Total Tyre Management programme—combining good purchasing, digital tracking, preventive maintenance, and analytics—can reduce tyre‐related expenditure by around 30% (or more) due to:

- Extending tyre life;

- Reducing fuel waste;

- Minimizing unplanned downtime and repair costs;

- Cutting administrative/inventory wastage;

- Optimizing purchase and lifecycle decisions.

With a platform like TyreBook facilitating the ecosystem (supply, services, data), fleet operators can leverage economies of scale, better visibility, and standardization to achieve these savings more reliably.